Low-voltage frequency converters are mainly composed of the following parts

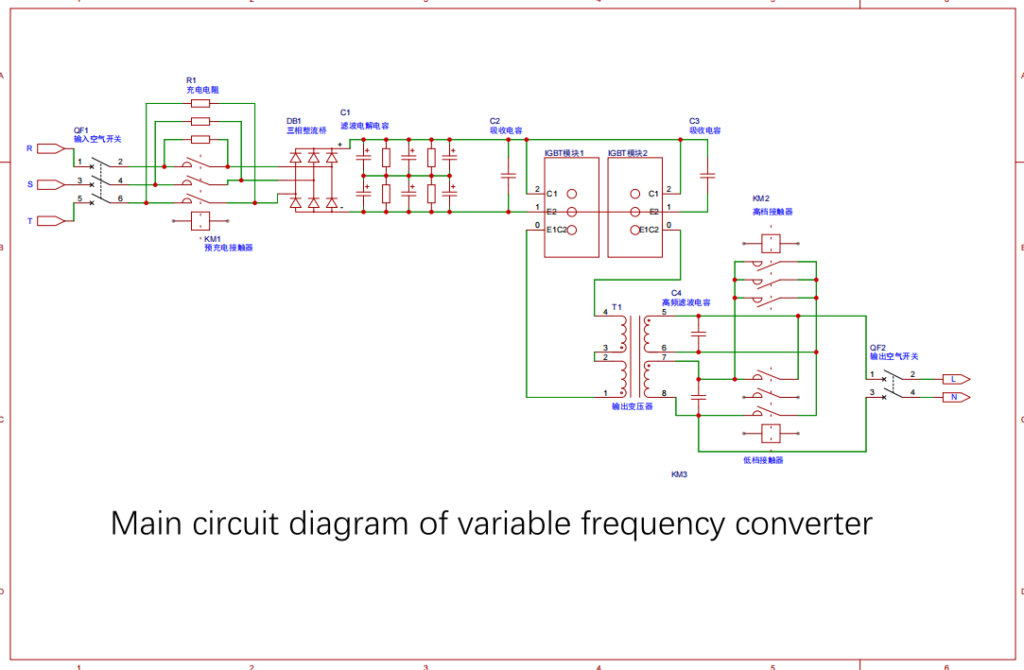

1.Rectifier bridge and filtering capacitor:

The three-phase AC power from the grid is fed into the frequency converter, the AC power is converted into DC power through the rectifier bridge, and the DC power is filtered through the filtering capacitor, which makes it smoother and ensures the normal work of the subsequent circuits.

2. Inverter

The frequency converter is a device that converts DC into AC and is the core component of the frequency converter, which realizes the adjustment of the output voltage and frequency of the frequency converter, thus realizing the adjustment of the motor speed.

The frequency converter usually adopts three-phase bridge frequency converter, through adjusting the opening angle of thyristor or MOSFET and other devices, control the output voltage and frequency size, to achieve the purpose of stepless speed regulation.

3. Controller

The controller is the center of operation and control of the frequency converter, which is mainly responsible for collecting and processing external control signals, controlling the output voltage and frequency of the frequency converter, and adjusting the speed of the motor.

Controller is generally composed of microprocessor and various control devices, real-time monitoring of the frequency converter’s operating status and performance parameters, with a strong real-time and reliability.

4. Analog-to-digital converter

Analog-to-digital converter is a key component in the frequency converter, which is mainly used for data acquisition and processing of control signals in the frequency converter and converting them into digital signals so as to facilitate the input and processing of the controller, and to improve the accuracy and stability of control.

5. Protection components

The protection components of the frequency converter mainly include overload protection, current limitation, overheating protection, short circuit protection, etc., and their existence can effectively guarantee the operation safety of the frequency converter and prevent accidental damage or personal injury accidents.

6. Failure diagnosis components

Failure diagnosis components are mainly used for real-time monitoring of frequency converter failure conditions, such as temperature, battery power, communication conditions.

This is quite helpful for repairing mechanical failures and preventing mechanical failures.

The above are the more important components of the low-voltage frequency converter, and there may be slight differences between different brands and models of frequency converters.

Low-voltage frequency converter function

Low-voltage frequency converter is a kind of electric equipment used to control the rotational speed of AC motor, which has the following functions:

1. Frequency control

Through frequency conversion technology, it can control the running frequency and voltage of AC motor and realize the functions of fixed speed, variable speed, acceleration, deceleration and reversal of motor.

2. Input/output signal processing

It can process various sensor signals, safety circuits and external control signals, diagnose faults and operation errors, and ensure the safety and reliability of the equipment.

3. Voltage and frequency stabilization

The frequency converter has built-in voltage and frequency stabilization functions, which can prevent the influence of unstable power grid and provide a stable operating environment for the motor.

4. Feedback control

Open-loop and closed-loop feedback control can be used to realize the control requirements in various application scenarios, including fixed-speed control, closed-loop current control, vector control and magnetic field orientation control.

5. Communication control

Through a variety of communication interfaces and protocols, it can realize communication and linkage control with upper computer, PLC and human-machine interface.

6. Overload and short-circuit protection

Realize the safety protection of the motor and its peripheral equipment through a variety of protection functions, such as overload protection, short-circuit protection and overheating protection.