Shore power technology means that the power supply from the ship’s generator is deactivated while the ship is in port. Shore power is supplied to the ship’s electrical equipment through cables from the quay (port).

Research on shore power supply technology in ports has a very positive significance on energy saving and emission reduction, building green ports, and it is an important measure to solve the problem of pollution in harbor waters caused by power generation on board ships docked at ports.

At present, the world’s shore power mainly consists of 60Hz and 50Hz port power grids supplying power directly to 60Hz and 50Hz ship power grids respectively, neither of which involves frequency conversion technology.

Generator sets on shore are usually used to provide 60Hz power supply, but this method is high, noisy, and will also cause serious pollution of the land environment, low power generation efficiency and high maintenance costs.

With the continuous development of modern power electronic technology and microelectronic control technology, the high-power inverter circuit (over 400kW) using IGBT as power device is widely used in the field of frequency conversion and speed regulation, which lays a solid foundation for the new type of onshore power supply technology – inverter power supply to replace the genset.

I.New shore power supply technology – inverter power supply

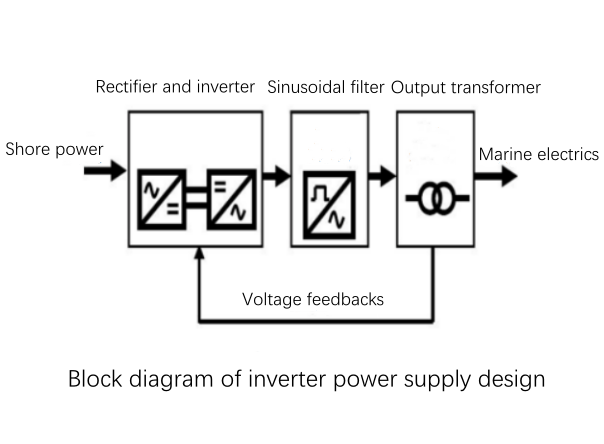

An inverter power supply that undergoes AC-DC-AC conversion is called an inverter power supply.

The main function of an inverter power supply is to convert the existing AC grid power into the frequency required by the user.

Inverter power supply is used as a standard power supply, to ensure that the power output waveform stability and purity, to provide the best power supply environment.

The inverter power supply technically uses a

universal inverter as the rectifier and inverter unit

with the following characteristics.

1) The quality and operation of the frequency converter are reliable, the production scale is large, the after-sales service network is sound and the spare parts are sufficient.

2) The inverter power supply unit adopts dry type isolation transformer, which can effectively prevent the mutual interference between the shipboard load grid and shore power grid, and avoid the inverter power supply unit from being damaged due to the failure of the load equipment.

3) Several major components selected for the power supply design are mature products with high reliability, and the system has a simple structure and clear lines, which is convenient for daily maintenance, diagnosis and repair.

4) The output frequency and voltage of the variable frequency power supply unit can be adjusted within a certain range, especially in the case of line voltage loss when used in shipyards, the set value can be adjusted and the voltage can be raised to compensate.

II.Technical solutions for inverter power supplies

1.Design principles

Adopting Finnish VACON general-purpose frequency converter, through the programming of frequency converter software application macros, the ordinary frequency converter has the function of using frequency conversion power supply. At the same time, the sine wave filter and output transformer are configured to convert AC380V/50Hz shore power into AC440V/60Hz ship power.

2.Typical inverter power supply application single line diagram

In practice, a complete inverter power supply unit mainly consists of 5 parts, namely: input inlet switchgear, inverter cabinet (including rectifier and inverter unit), output isolation transformer cabinet, sine wave filter and output switchgear.

If the input is a high-voltage power supply, a high-voltage switchgear cabinet and transformer are also added at the input. Except for the frequency converter, all other components use passive components, which have extremely high reliability and stability.

III.Frequency converter application macros

Adopting general-purpose inverter, through the programming of inverter application macros, such as adapting the speed (frequency) PID regulation function of general-purpose inverter to voltage PID regulation control, so that the ordinary inverter has the function of using inverter power supply.

Impact of starting currents of electrical equipment on inverter power supplies

Generally, the starting current of power equipment is more than 4 times of the rated current at the moment of starting, which only reduces the output voltage for the generator set and does not affect the normal operation of the generator.

However, for the inverter power supply using IGBT as the power device, the current exceeds the limit of the protective tripping will occur. Therefore, when designing and using the inverter power supply, it is necessary to give full consideration to the specific load conditions.

1) When designing, select the inverter according to the rated power and starting current of the load. Generally the maximum limit current of the frequency converter is 1.5 times of its rated current, choose the appropriate power of the frequency converter not only to protect the frequency converter, but also not because of the equipment starting overcurrent and tripping.

2) When used, high-power equipment should adopt soft starting measures (such as reduced voltage starting, etc.), should try to avoid multiple equipment starting at the same time and frequent starting.

3) Take effective heat dissipation measures to prevent overheating of high-power components, especially after tripping, do not start again immediately.

IV.Environmental benefits and economic analysis

1.Environmental benefit

The actual significance of ship power supply for ports lies in the reduction of exhaust gas emissions.The average power consumption of 4250TEU container ships during port calls is 1000kW.

The berth utilization rate is determined in accordance with the Ministry of Transportation’s “Technical Specification for Port Engineering” to determine the range of values, and take the compromise value of 0.58, with annual ship calls of 366×0.58=212d, which translates into hours of 24h×212=5088h. 20891-2007 stipulates that the emission limit value of diesel engine exhaust pollutants for non-road mobile machinery is 3.5g CO, 1.0g HC, 6.0g NOx, 0.2g PM, and the total amount of flue gases is 10.7g.

Calculation shows that the annual emission reduction of single berth is 54.44t (including CO, HC, NOx and PM).

2.Economic analysis

The ship’s power supply is based on a single berth power of 1000kW at RMB 1.10 per kWh. The fuel consumption rate of Wärtsilä four-stroke diesel engine is about 200l/kW-h. On May 20, 2022, Bunkerworld reported that the price of MGO oil in Shanghai port is 547.50 USD/t, and the price of IFO 380 oil is 381.50 USD/t.

According to the exchange rate of CNY to US dollar, 6.8251, that is, the price of MGO oil is 3736.74 Yuan/t, and the price of IFO 380 oil is 2603.77 Yuan/t.

Generally, the density of standard diesel oil is about 0.86kg/l, so the density of MGO oil is around 0.86kg/l. Generally speaking, the density of standard diesel fuel is around 0.86kg/l, so the price of MGO fuel is 3.21 RMB/l and IFO 380 fuel is 2.24 RMB/l.

Considering the increasingly strict emission regulations, if all the ship’s electricity and power supply use Marine Gasoline (MGO), especially if the price of MGO fuel is increased to 1,200 USD/l, the annual saving of energy cost (7 RMB/l) will be calculated, and the annual saving of energy cost (1,000 USD/l) will be calculated.

Considering the increasingly strict emission regulations, if all the ship’s electricity is used by marine gasoline (MGO), especially after the MGO oil price rises to $1200/t, the oil cost will be calculated at $7/l.Annual energy cost savings for ships (1400-1100)*24 x 212 = $1,526,000, while shore power will reflect its economic nature.