By measuring the operating voltage and current, it is possible to determine the effectiveness of the application of the relevant electronic components as well as the cause of control circuit problems.

Dangerous accidents can easily occur when operating voltages or currents are too high and out of the standard range in the use of frequency converter.

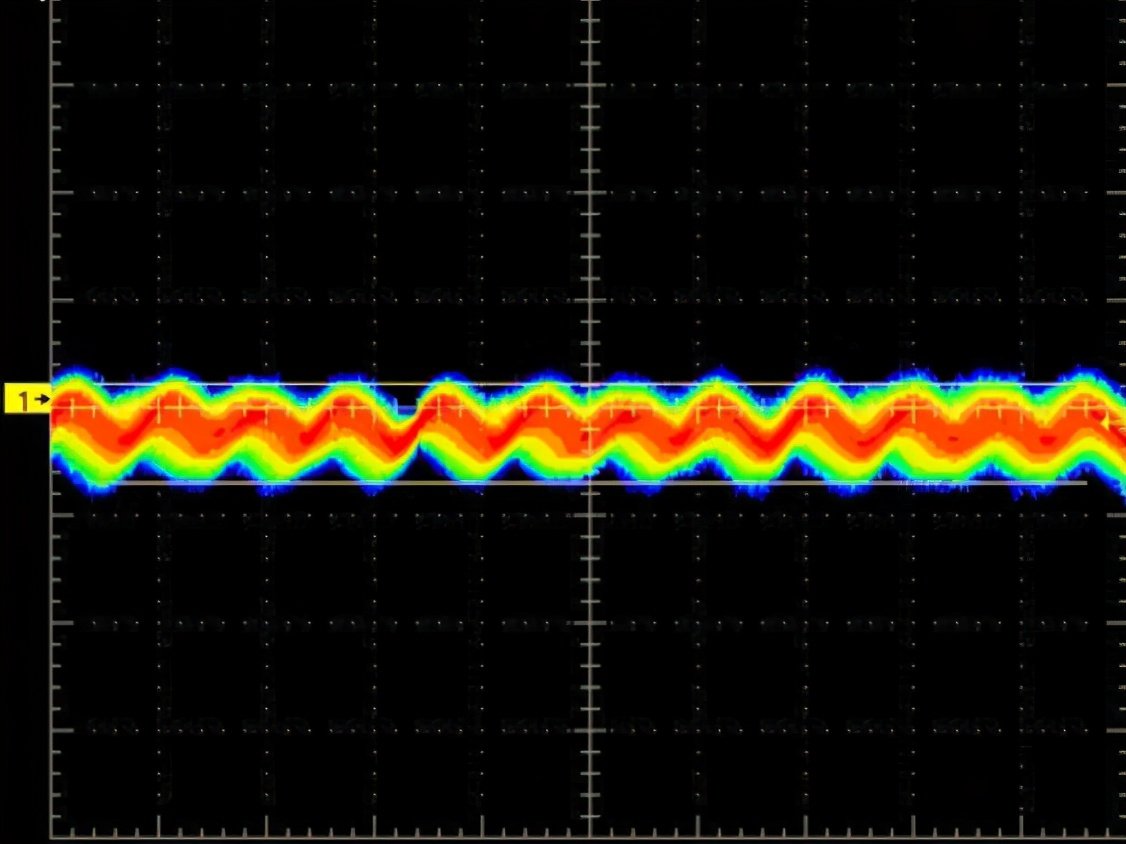

Therefore, there is an increasing need to measure the operating voltage and to monitor changes in the value of the operating voltage, and the entire process used to measure the ripple voltage of frequency converter is described in detail next.

1. You can first use a digital oscilloscope to acquire all the waveforms, and then zoom in to observe and measure the waveforms (automatic or cursor measurement are both possible), and also need to use the FFT function of the digital oscilloscope from the frequency domain analysis to perform the operation.

Often use bandwidth limiting is usually used to indicate ripple, so avoid picking up high-frequency noise that is not actually present, and set the correct bandwidth limit for the digital oscilloscope used for the measurement.

2. Remove the probe cap and assemble the oscilloscope so that the antenna formed by the long ground cable can be eliminated by wrapping a small piece of wire around the probe’s ground point and connecting the ground wire to the power supply.

This reduces the length of the tip exposed to high electromagnetic radiation around the power supply unit, thus further reducing the number of pickup waves.

3. In the isolated variable frequency AC converter, will form a large number of common mode current flow through the probe’s grounding point, in the power supply between the grounding point and the digital oscilloscope’s grounding point there is a voltage drop, can be expressed as ripple.

To avoid this problem, special attention should be paid to the common mode filtering in the power supply design.

4. In addition, winding the digital oscilloscope leads around a ferrite core helps minimize such currents and creates a common mode inductor.

It does not interfere with differential operating voltage measurements and reduces the chance of data errors caused by common mode currents.

5. Power supply ripple performance may improve when integrated into a system. In most cases, there will be some inductance between the frequency AC converter and other components of the system.

This inductance can be present in the wiring or etched into the circuit board. There are always additional bypass capacitors around the chip which represent the load on the power supply unit.

Together, they form a low-pass filter that further reduces power supply ripple or high-frequency noise.

6. In addition, in special cases, when the current flows for a short time through the 15nH inductor and 10F bypass capacitor of one inch conductor, the cutoff frequency of this filter is 400kHz.

In this case, the high-frequency noise will be greatly reduced, and the cutoff frequency of the filter is lower than the ripple frequency of the power supply, so the ripple can be greatly reduced.

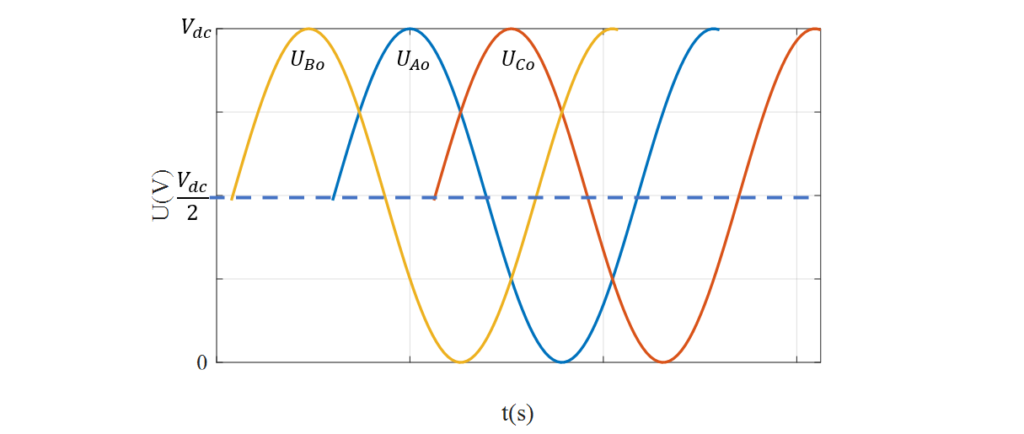

7, DC voltage output from the power supply should be a fixed value, but in most cases, after the rectification and filtering of AC voltage, there will be more or less residual AC components, including periodic and random components of the interference signal is called ripple, large ripple will affect the normal CPU and GPU operation, the smaller this value the better.

The above is the specific measurement process of frequency converter ripple voltage. Ripple voltage actually refers to the industrial frequency AC component contained in the DC output voltage, which affects the life of the capacitor and the quality of the output voltage, and requires special attention because it affects the effectiveness of the applied force.

In addition, when using digital oscilloscopes, care must be taken to ensure that the equipment is operated in a safe area to ensure the safety of both the equipment and the operator.