Frequency converter is a kind of power system equipment widely used in mechanical equipment, and its core function is to precisely adjust the speed of the motor by changing the frequency of voltage or current, so as to realize the drive and control of different types of mechanical equipment.

This technology combines the dual functions of inverter and converter, enabling the power output to flexibly adapt to the needs of different work scenarios.

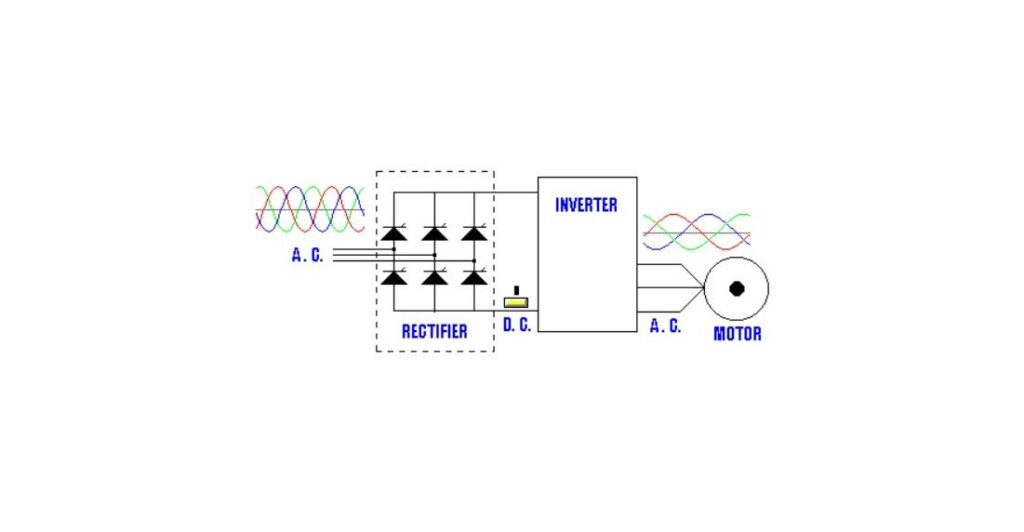

Specifically, the working principle of a frequency converter usually includes three processes: rectification, filtering and inversion.

First, the input AC power supply is converted into DC power supply through rectifier circuit; then, the DC power supply is filtered to remove the pulsating components and obtain smooth DC voltage; finally, the DC power supply is converted into AC power output with adjustable frequency and voltage by using the inverter circuit, so as to realize the precise control of the motor speed.

Frequency converter has a wide range of applications in a number of fields, such as the drive and control of fans, pumps, injection molding machines and other equipment in industrial manufacturing, electric vehicle motor drive systems in transportation, as well as inverter air conditioners and washing machines in household appliances.

Its use can significantly improve the operating efficiency of the equipment, reduce energy consumption and noise, while extending the service life of the equipment.

However, it is worth noting that frequency converters also need to consider some technical details and precautions during use, such as selecting appropriate control modes and adjusting parameters to ensure their normal operation and optimal performance.